Na'ura mai aunawa hangen nesa shine na'urar auna hangen nesa mai inganci, wanda aka yi amfani da shi sosai wajen auna ma'auni daban-daban.

IV. Features da Abvantbuwan amfãni

1. Babban madaidaici: Injin Ma'aunin hangen nesa yana da kayan aikin sarrafa madaidaicin matakin micron da software na aiki na ɗan adam, wanda zai iya cimma ma'auni mai mahimmanci.

2. Ma'aunin rashin sadarwa: Yana guje wa kurakurai da lalacewar da za a iya haifarwa ta hanyar ma'aunin hulɗar gargajiya.

3. Babban digiri na aiki da kai: Cikakken Ma'aunin Ma'aunin hangen nesa na atomatik zai iya kammala aikin ma'auni ta atomatik, ceton ma'aikata da inganta ingantaccen aiki.

Gomanceari: Ta amfani da mahimman rukunin bincike da Laser, hangen nesa na nuna girman geometrici mai girma da uku.

5. Sauƙaƙan aiki: Na'urar aunawar hangen nesa na dijital ta haɗa da ayyuka daban-daban sosai, yana sa aikin ya fi sauƙi da sauri.

V. Filin Aikace-aikace

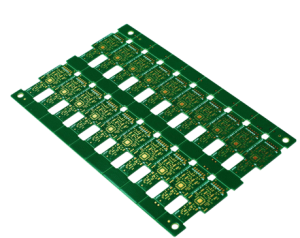

Vision Measuring Machine s ana amfani da ko'ina a cikin inji, Electronics, molds, allura gyare-gyare, hardware, roba, low-ƙarfin lantarki lantarki kayan, Magnetic kayan, daidaici hardware, daidaici stamping, haši, haši, tashoshi, mobile phones, gida kayan, kwamfuta, LCD TVs, buga kewaye allon, motoci, da sauran kayan aikin filin agogon kayan aiki.

Ana amfani da shi galibi don auna girman da kusurwar sassan da ke da wahala ko ba za a iya aunawa tare da ma'auni da masu mulki ba.

VI. Amfani da Kulawa

Lokacin amfani da na'urar aunawa hangen nesa, kula da waɗannan abubuwan:

1. Ya kamata a sanya kayan aiki a cikin ɗaki mai tsabta da bushe don guje wa gurɓatar sassan gani da tsatsa na sassan ƙarfe.

2. Bayan amfani da kayan aiki, ya kamata a shafe shi da tsabta kuma an rufe shi da murfin ƙura.

3. Lubricate tsarin watsawa da ginshiƙan jagorar motsi na kayan aiki akai-akai don kiyaye shi cikin amfani mai kyau.

4. Madaidaicin sassan kayan aiki kamar tsarin hoto, bench, mai sarrafa gani, da dai sauransu suna buƙatar daidaitawa daidai. Bai kamata abokan ciniki su harhada shi da kansu ba. Idan akwai wata matsala, sanar da masana'anta don magance ta.

Lokacin aikawa: Satumba-27-2024